|

Tests at SPS Medical, an independent lab in Rush, N.Y., showed PPSU became

significantly yellowed and brittle after only 150 Sterrad NX cycles, while Ultem

HU1004 showed negligible yellowing or embrittlement after 300 cycles. PPSU

showed 10 times greater color shift than Ultem HU 1004 resin significantly

yellowing after only 100 Sterrad NX cycles.

With the Ultem HU1004 resin grade, Ultem resins are now one of the few materials

that can maintain its key performance properties after exposure to the four most

common techniques used in sterilization environments, including:

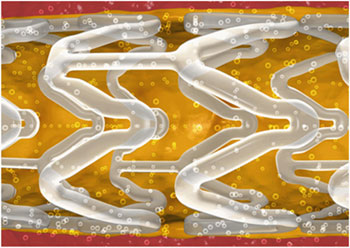

Finally, Abbott Vascular is working to develop a fully bioresorbable polylactic

acid (PLA) based stent. While there are three types of bioabsorbable stent

technologies under development - including bioabsorbable polymers to coat metal

stents, totally bioabsorbable metallic stents that corrode and totally

bioabsorbable polymer stents - many stent makers believe that fully dissolving

polymer stents are the long term solution. Metal stents are foreign objects that

can:

-

Irritate vessels and cause stent thrombosis

-

Prevent vessel remodeling

-

Prevent future surgical interventions

-

Can fatigue and suffer strut fractures, and impair CT or MR imaging

For these reasons, several stent manufacturers are working on biodegradable

stents that do not leave behind any hardware. The main challenge with a fully

dissolving polymer stent is to maintain radial strength to keep the vessel open

long enough to prevent renarrowing.

Abbott is using stretch blowmolding to enhance physical properties of PLA used

to develop its Absorb bioresorbable vascular stent. The stent needs to remain

intact for 3-6 months to support artery walls until they can stay open on their

own and dispense drugs that maintain artery health. The entire drug is fully

eluted in 120 days. The PLA is fully broken down within two years into water and

CO2.

PLA degradation rates can be adjusted by changing the ratio of crystalline

material in the PLA - the amorphous zones in the PLA breakdown at a different

rate than the semi-crystalline zones. Abbott is using strain induced

crystallization in the stretch blowmolding process to alter the crystalline

material ratio in the PLA. PLA strength is also tailored to provide the

necessary vascular wall support and to withstand the sterilization process.

Abbott commercialized the international launch of its Absorb bioresorbable

vascular scaffold, now widely available across Europe and parts of the Asia

Pacific and Latin America. Abbott is referring to Absorb as a scaffold to

indicate that it is a temporary structure, unlike a stent which is a permanent

implant.

The international launch of Absorb followed a medical trial program that

encompassed five studies in more than 20 countries. Abbott says that study data

indicate that Absorb performs similar to a best-in-class drug-eluting stent on

tests such as major adverse cardiovascular events (MACE) and target lesion

revascularization (TLR).

Abbott Vascular

Absorb bioresorbable vascular scaffold

http://exclusive.multibriefs.com/content/medical-device-plastic-material-innovations-to-watch

|