|

These medical elastomers can replace thermoset rubber used for tiny plunger tips

or seals that prevent drugs in the tube or barrel of the syringe from flowing

backward as the plunger is depressed. Their good COF also eliminates coating

requirements that might otherwise interact with drug contents of syringes.

These materials also exhibit lower oxygen absorption than nonvulcanizate TPEs

(thermoplastic elastomers), thereby affording greater protection of

pharmaceutical contents when used in seals or gaskets for vials. They also

exhibit greater resilience than other TPEs, perform well in high-temperature end

uses, are more chemical-resistant and can be sterilized in steam, autoclave, or

gamma irradiation processes.

Continuing, polybutylene terephthalate (PBT) resin tailored for medical device

dimensional accuracy is another innovative medical material use example. BASF's

Ultradur B4520 PRO is a recently introduced PBT for injection-molded

applications in medical technology. Its high dimensional stability and optimized

shrinkage behavior meet the stricter reproducible dimensional accuracy

requirements for medical device components. Other property features are as

follows:

-

Sterilized with ionizing gamma radiation or ethylene oxide

-

Can easily be printed on

-

Broad chemical resistance to polar and non-polar solvents

-

Low water/moisture absorption

-

Ideal sliding, due to high friction and wear resistance (depending on the

sliding partner)

-

Excellent heat aging behavior

-

Good moldability with fast cycles

BASF

Functional and mechanical components for insulin pen

Possible medical applications include:

-

Functional and mechanical components with high dimensional precision and

stability for use in drug delivery systems such as insulin pens, inhalers or

metering devices

-

Device components such as manifolds, screws, sleeves, valves, plungers, lancets

or caps

-

Chassis and housings

-

Filter systems

-

Drug containers

-

Pharmaceutical closures

-

Technical disposable applications

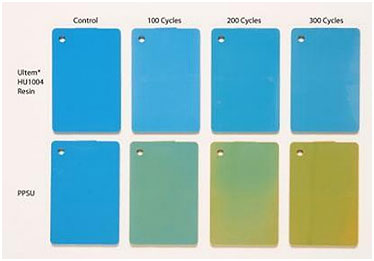

Next, polyetherimide (PEI) resisting H2O2 gas plasma sterilization is an

interesting medical plastics material advance. A transparent, high-temperature

thermoplastic, PEl resin blend Ultem HU 1004 from Sabic Innovative Plastics with

improved impact resistance and enhanced hydrostability has been developed for

healthcare applications. Recent tests show that this medical-grade PEI resists

hydrogen peroxide (H2O2) gas plasma sterilization better than polyphenylsulfone

(PPSU) another amorphous high temperature engineering thermoplastic.

There is growing interest in this newer sterilization technique - known

commercially as Sterrad NX, a tradename of Advanced Sterilization Products.

Because this new sterilization technique is a dry, low-heat process, it can be

used to sterilize sensitive electrosurgical devices such as cameras.

Sabic Innovative Plastics/UL IDES

Ultem HU1004 (top row) shows almost no color change from

100 to 300 Sterrad NX

cycles, while PPSU (bottom row)

shows yellowing as early as 100 cycles.

Next

|