|

Global Medical Injection Molding

Market

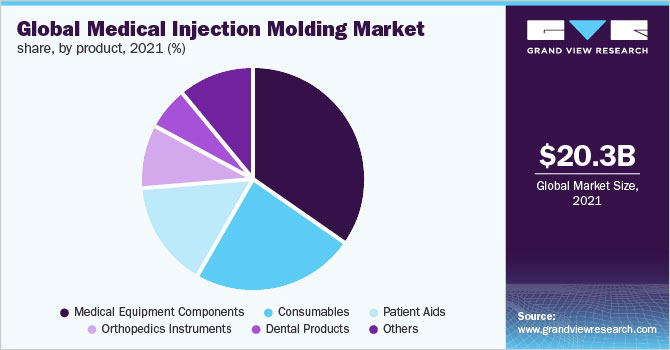

As per a recent report by “ Grand

View Research”, the global medical injection molding market size was estimated

at USD 20.30 billion in 2021 and is expected to expand at a compound annual

growth rate (CAGR) of 5.7% from 2022 to 2030.

This growth is poised to be

driven by the demand for mass production of identical medical components with

design flexibility and precision at lower costs. The number of hospital visits

and hospitalizations has increased manifold since the advent of the COVID-19

pandemic.

This has augmented the demand for various devices in

emergency room products, MRI equipment, drug delivery systems, and surgical

devices, among other devices used in hospitals.

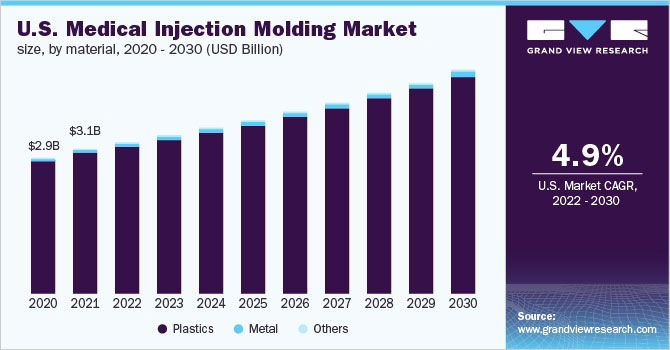

The market in the U.S. has undergone a

transformation as a result of the COVID-19 pandemic, with players acquiring and

expanding their capacity to satisfy the market's growing demands.

The regional industry is predicted to witness growth

in the coming years, owing to various factors such as the increasing number of

manufacturers adopting medical injection molding technology, the rising demand

for medical equipment, and the rising healthcare expenditure in the country.

Medical-grade products, components, equipment, and

tools require a production process that meets medical hygiene standards.

Injection molding is a viable approach for producing complex medical products,

components, equipment, and tools. Medical-grade injection-molded products are in

high demand globally because they are long-lasting and are inherently resistant

to pollutants and chemicals. These factors are expected to boost the industry

demand.

Medical injection molding (MIM) can be utilized to

develop complicated and basic medical devices. In general, it is best suited for

pieces that have thickness and weight less than 6 mm thick and 100 g,

respectively. However, the advent of new binder removal procedures has enabled

the processing of cross sections of parts of medical devices that are larger

than 12.5 mm and weigh up to 400 g.

In-house injection molding of injection molded

components by OEMs can be a considerable issue in terms of productivity, cost,

and quality. Many companies are outsourcing injection molding services because

it provides benefits such as strategic optimization, reduced inventory,

economies of scale, quick startup time, and increased quality.

Material Insights

The plastics material segment led the industry and

accounted for 98.8% of the global revenue share in 2020. Plastic injection

molding is a viable approach for producing complex medical products.

Medical-grade injection-molded goods are in high demand because they are

long-lasting, inherently resistant to pollutants and chemicals, and provide

economies of scale to major manufacturing companies.

The rising use of engineering-grade plastic resins

for medical and pharmaceutical products is due to factors such as

hightemperature endurance, metal tolerance, and high tensile strength.

Furthermore, these resins allow for a reduction in product weight, manufacturing

waste, and manufacturing costs, leading to their use in medical device injection

molding.

The demand for metals in the manufacturing process

is likely to grow at a CAGR of 8.2% during the forecast period. Metal injection

molding is an excellent method for producing delicate, tiny, and precision metal

components for the medical industry. The metal injection molding process employs

both thermoplastic and powder metallurgy injection molding.

System Insights

Hot runner systems led the medical injection molding

market and accounted for more than 57.8% of the global revenue share in 2020.

The growth is attributed to various advantages of these systems, such as faster

cycle time and lower pressure required to drive the molten mixture into the mold

cavity, elimination of waste due to the elimination of runners, the housing of

larger parts with greater volume of production, and an increase in the

uniformity & quality of parts.

Hot sprinter molds are made up of two plates that

are heated by a sophisticated structure. This structure keeps liquid

thermoplastics at the same temperature as their warming chamber. There are two

types of hot sprinters: inside warmed sprinters and distantly warmed sprinters.

The hot sprinter framework keeps the material in a liquid state throughout the

sprinter method, until it enters the form pit.

The cold runner system market is likely to advance

at a CAGR of 5.4% during the forecast period. The use of a cold runner system is

based on its benefits such as ease of maintenance and cost effectiveness; it is

suited for a wide range of polymers. This technology is a viable choice because

it produces higher-quality parts. As a result of reduced initial investments

compared to other systems, the use of cold runner systems is increasing at a

rapid pace.

A cold runner system is a physical tube that is not

heated and is used to inject plastic through a sprue. Its mold base is made up

of two or three plates. The injection technique employs molten thermoplastic,

which is injected into the molds through a nozzle via a sprue. Runners are kept

at the same temperature as molds in this system.

Product Insights

The medical equipment components segment led the

market and accounted for around 34.9% of the global revenue share in 2021.

Pharmaceutical companies having a presence in the United States include 3M

Health Care Business, Johnson & Johnson, Abbott Laboratories, and Pfizer Inc.

Ongoing improvements in the field of surgery, such as standardization of methods

and technical advancements, are expected to propel the medical sector forward

and fuel the demand for these products.

The in-house injection molding of injection molded

components by OEMs can be a considerable issue in terms of productivity, cost,

and quality. Many companies are outsourcing injection molding services because

it provides streamlined inventory, optimization, economies of scale, quick

start-up time, and enhanced quality, among other benefits, all of which are

projected to drive industry demand throughout the forecast period.

The increasing geriatric population globally that is

suffering from oral diseases, demand for medical tourism relating to dental

treatment, and the launch of multiple initiatives for oral health care for the

public by the government, are few of the growth enablers for the industry.

Furthermore, people are becoming more conscious of cosmetic dental treatment,

which helps to improve looks and keep fresh breath, which is expected to boost

the industry growth.

Regional Insights

Asia Pacific led the market and accounted for 40.6%

of the global revenue share in 2021. The healthcare industry in the region is

expected to grow at a swift pace owing to several factors, including the aging

population coupled with urbanization, improving the standard of living, and

expanding healthcare infrastructure in countries such as China, India, and

Japan.

The ongoing COVID-19 pandemic has further increased

hospitalization and in turn boosted the demand for disposable medical devices,

thereby propelling the industry growth.

In North America, the rising healthcare costs and an

aging population are expected to boost the medical sector. Government

authorities are anticipated to invest considerably in healthcare facilities

following the COVID-19 pandemic. The increasing use of injection molding to

manufacture a variety of parts and components for medical devices is likely to

boost industry growth in the coming years.

The medical industry in the U.S. is among the most

technically advanced in the world, thereby contributing to the surging demand

for medical devices. Moreover, it has a high per capita income, along with

increased health awareness among the masses. All these factors contribute to the

augmented adoption of this technology in the healthcare sector, thereby boosting

industry growth.

The regulatory framework for the medical device

sector in Europe is being changed, with the goal of raising medical device

safety and performance standards. As a result, during the forecast period,

demand for high-quality, biocompatible, recyclable, and innovative plastics in

medical devices is expected to increase, which is expected to boost medical

injection molding services.

( Re :

https://www.grandviewresearch.com/industry-analysis/medical-injection-molding-market

)

|