|

New Medical Device Standard Puts Health Care at Risk

Most medical device manufacturers are small and vulnerable to high costs of

compliance

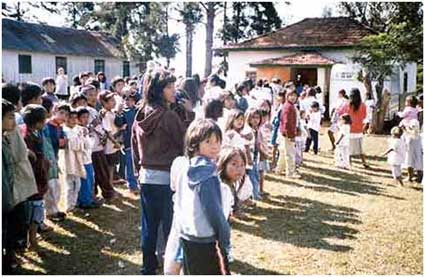

One of the greatest challenges that I have in discussing

standards is trying to put things in a context so that all people affected by

them can understand how they matter. So I want to start with a simple picture

and a remarkable snapshot in time. It shows how small medical-device companies

are making major contributions to health care, and begins another story that

explains how one standard is threatening to undo these gains.

The photograph below was taken in Brazil, by a team of

missionary dentists that brought a new portable dental system to their village.

At first, no one came; in fact, I was told most of the children were terrified.

In some places like this village, “dentistry” means getting teeth pulled with a

pair of pliers. When word got around that a new dental system was being used,

and that the children could get their teeth fixed, not pulled, the lines grew so

long, the children could no longer fit in the picture. Many people may not know

this, but this is a typical experience for many dentists working in remote

locations. The World Health Organization has indicated that the most prevalent

childhood disease is dental caries (tooth decay). So when dental care arrives in

a remote area, so do the crowds.

This picture fits with my discussion as to how technical

standards are used in medical-device regulations. These regulations apply to

anything used in the treatment of patients. From tongue depressors to dental

hand pieces, from thermometers to pacemakers-if it’s used for treating a medical

condition, it’s a medical device. Because this is such a critical area to

regulate in any society, it’s more important than ever to make sure that these

devices are safe and effective. That’s why medical-device regulations are among

the most strenuously enforced and challenging regulations in the world. However,

since only 10 percent of medical devices are considered “high risk” (e.g.,

critical life support equipment), regulatory agencies try to be sensitive to

make sure that the majority of lower-risk medical device are not overly

regulated, which can have a bad effect on the health care system. Doctors and

patients need these devices. About 80 percent of medical-device manufacturers

are small companies, and they develop half of all the new innovations that reach

our doctors. They are also the most vulnerable to costs of compliance.

Dental units, like the one used in Brazil, are considered a

low-medium risk, and they are made only by small manufacturers. They are not

entirely without risk, though, since they have air-compressors that can get hot,

and they are powered by electricity, which can, under certain unusual

conditions, become a shock hazard. In fact, some regulatory authorities require

that these types of devices be tested to a basic safety standard, to make sure

they do not present electrical or mechanical hazards.

Testing can cost thousands of dollars. Medical devices are

normally tested against a standard from the International Electrotechnical

Commission (IEC) titled IEC 60601-1-“Medical electrical equipment, Part

1-General requirements for basic safety and essential performance.” In the

testing lab, safety testing engineers use humidity chambers, induce simulated

fault conditions, and measure temperatures and electrical currents to see

whether the equipment remains within the safety limits of the standard.

Standards are used by medical-device regulators to gain confidence in a

product’s safety. Testing the dental unit sold to Brazil cost nearly $12,000 in

2002. It was considered the most expensive testing ever undertaken, but since

the testing labs all charged the same, it had to be paid. If the product had not

gone through the testing, the product could not have been legally sold in

Brazil, where product testing to IEC 60601-1 is a regulatory requirement.

This brings us back to the photograph. The impact on health

care in Brazil and many other countries is directly influenced by the cost of

applying standards. This is one of the biggest problems affecting health care to

date. Testing labs are private companies with an interest in growth. A more

expensive standard supports their growth, while hampering medical device

manufacturers trying to legally provide their equipment to doctors.

In fact, the IEC 60601–1 standard has been completely overhauled since the

above dental unit was tested. Testing the same unit that went to Brazil would

now cost closer to $39,000 if the new, third edition of IEC 60601-1 is put into

force. One executive at the company that made this dental unit indicated that

they would not sell to any country that required testing to the third edition of

IEC 60601–1. Had it been required in 2002, the children in this picture would

have been hiding from the dreaded pliers instead of getting their teeth fixed.

http://www.qualitydigest.com/inside/health-care-article/new-medical-device-standard-puts-health-care-risk.html |