|

Polymeric

Biomaterials For 3D Printing In Medicine

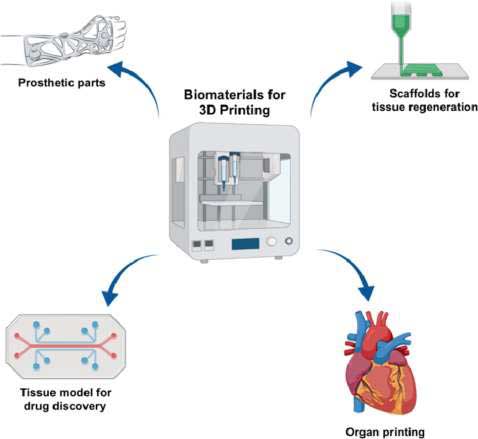

3D printing is rocking the field of tissue

engineering, regenerative medicine, and rehabilitation allowing fabrication of

modular and patient-specific scaffolds, orthoses, and prosthesis with high

structural complexity and design flexibility. Since Charles Hull initially

developed 3D printing technology in 1984 using stereolithography, 3D printing

has expanding at accelerating pace in a wide range of applications in medicine,

including craniofacial implants, dental molds, prosthetic parts, on-demand

medical equipment, surgical models, scaffolds for tissue regeneration, organ

printing, implantable biosensors, and tissue models for drug discovery.

This is due to the potential of 3D printing to

provide patientspecific designs, high structural complexity, and rapid ondemand

fabrication at a low-cost. However, one of the major bottlenecks that limits the

widespread acceptance of 3D printing for biomedical manufacturing is the lack of

polymers, biomaterials, hydrogels, and bioinks functional for 3D printing,

biocompatible, and more performing from the biomechanical point of view to meet

the different needs.

. .

Although much progress has been made with 3D

printing technology, there are still remarkable issues to overcome (such as

standardization and integration of an entire biofabrication platform, software

design, capabilities of the 3D printers, reproducibility, quality by design,

biomaterials characterization, and regulatory hurdles) before it can be

recognized as a conventional biofabrication technique in medicine and reach the

medical market. Among these issues, the major bottleneck is the lack of

heterogeneity biomaterials allowing their reliable clinical use.

Generally, printable materials as polymers,

hydrogels, or bioinks must: (1) have adequate viscosity that allows being

printable and structurally stable, (2) have the capability to form 3D structure

within a few minutes, (3) have the possibility of being mechanically reinforced

through UV irradiation, biological (e.g. transglutaminase, sortase, tyrosinase,

lysil-amine oxidase), or chemical (e.g. Michael-type addition, thiolene

reaction, orthogonal reaction) cross-linking, (4) have tunable mechanical

properties, (5) be biocompatible, (6) have adequate degradation kinetics, (7)

form nontoxic degradation byproducts, (8) be biomimetic, and (9) be able to

control release molecules or drugs. In addition, biomaterial inks should be

easily manufactured and processed, affordable, and commercially available.

In this context, 3D printing can transform

healthcare through personalized medicine, thus improving patient compliance by

tailoring the medication to the patient. This can be achieved through on-demand

manufacturing in clinical settings to offer the best medical care .

3D printable materials

Solid polymers-based inks

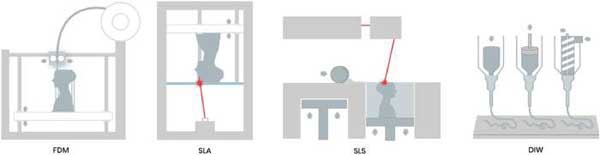

Polymers are the most common types of biomaterials

used in 3D printing technologies [57, 58], since they come in the form of

filaments for fused deposition modeling (FDM), powder-beads for selective laser

sintering (SLS), solutions for stereolithography (SLA), and gels for direct ink

writing (DIW) (Fig. 2). Further, they are biocompatible, have tunable mechanical

properties, degradation rates, and can be dissolved in rapidly evaporating

organic solvents such as dichloromethane, tetrahydrofuran or dimethyl sulfoxide.

Fig. . Schematic representation of 3D printing

techniques. (a) Fused deposition modeling (FDM), (b) stereolithography (SLA),

(c) selective laser sintering (SLS), and (d) direct ink writing (DIW). Table 1.

Common polymers used in 3D printing and their properties

|

Name |

Melting point |

Stiffness |

Limitation |

Advantages |

|

ABS |

105 °C |

30 MPa |

Not

biodegradable and shrinks in contact with air. |

Good

strength and flexibility. |

|

PLA |

175 °C |

230 MPa |

Long-term biocompatibility. |

Good

mechanical properties; Low cost. |

|

PCL |

60 °C |

216 MPa |

Long

degradation time (3 years). |

Excellent rheological and viscoelastic properties upon heating; Low cost. |

|

PC |

110 °C |

2250

MPa |

Absorb

moisture from the air affecting performance and printing resistance. |

Tunable

mechanics and porosity. |

|

PEEK |

350 °C |

3.6 GPa |

High

melting point. |

High

mechanical and thermal resistance; Very strong and at the same time much

lighter than some metals. |

|

PP |

165 °C |

1.6 GPa |

Low

temperature resistance; Sensitivity to UV rays. |

Lightweight. |

|

Polyamides |

250 °C |

10 MPa |

Most

used for SLS technology. |

Good

stability, flexibility, and shock resistance. |

|

TPU |

235 °C |

100 MPa |

Cannot

withstand high temperatures. |

Tunable

stiffness. |

Polymeric hydrogel-based inks

Hydrogels are 3D cross-linked polymer networks,

which can absorb and retain large amounts of water (> 90%) . Commonly hydrogels

are held together by: (1) hydrogen bonds; (2) electrostatic interactions; (3)

hydrophobic interactions; (4) watermediated hydrogen bonds; (5) van der Waals

interactions; (6) covalent cross-links; or (7) a combination of the above

interactions . Hydrogels provide ideal “soft material” systems to mimic native

extracellular matrix (ECM) microenvironments due to their biocompatibility,

tunable mechanics, and degradation. Additionally, they are able to easily

incorporate bioactive cues (i.e. RGDS, IKVAV, and DGEA) or other bio-molecular

structures such as nucleic acids, fatty acids, glycans, and growth factors to

form biomimetic supramolecular scaffolds . Finally, some hydrogels are

shear-thinning and thixotropic: useful properties for bioprinting.

(Abstracted from Ref :

https://www.sciencedirect.com/science/article/pii/S2666964121000060 )

|

|