|

Precision Extrusion For

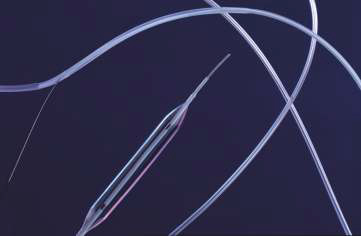

Thin-Walled Catheter Manufacturing

Thin-walled catheters are a requirement of many

minimally invasive cardiovascular, neurovascular, and endovascular procedures. Thin-walled catheters are a requirement of many

minimally invasive cardiovascular, neurovascular, and endovascular procedures.

Catheters are used in a wide range of minimally

invasive procedures as a tool for transporting treatments and therapies through

small vasculatures to difficult-to reach areas of the body such as the lower leg

or brain.

There are several design challenges involved in

catheter development, one of the most notable being the need for inside

diameters wide enough to allow for the movement of therapeutic devices and

implants all while ensuring that outside diameters – which are entirely limited

by blood vessel anatomy – remain acceptable.

Faced with this challenge, device developers have

set on thin walled catheter designs as the solution. Such designs also

facilitate a high degree of flexibility in the tube, perfect in demanding

surgical procedures.

When producing thin-walled catheters, careful

execution of the extrusion process with a strong focus on tight tolerances takes

utmost importance. The specifications usually test the limits of free-form

extrusion, which depends on air pressure within the tube. Instead, an

over-extrusion process assisted by mandrels can be a more reliable way to

control the profile.

Mandrel - assisted extrusion

Mandrels are cylindrical, tapered rods, typically

made of stainless steel. In catheter forming, mandrels provide support and

control of the inside diameter. Once the catheter has been built, the mandrel is

removed, leaving behind a consistent hollow tube with a smooth inner surface.

Some mandrels are produced with a PTFE coating to facilitate easy removal.

Using specially designed mandrels in manufacturing

can also help to deliver more complex catheter designs, such as those with

tapered profiles. According to leading medical wire contract manufacturer Custom

Wire Technologies (CWT), mandrels tend to have the most unique design requests

of the products it manufactures. Requests often include tapers, steps, radii,

flats, and D-shapes.

While many catheter manufacturers use traditional

wire mandrels, some opt for a cost-effective plastic. When it comes to producing

microcatheters, wire is typically preferred due to its ability to be processed

to smaller diameters. In addition, metal mandrels are essential in applications

that involve high processing temperatures, where plastic would melt.

https://www.medicaldevice-network.com/sponsored/thinwalled-catheter-manufacturing/ |